Battery testing chambers

Battery Test Chamber

Batteries are the future of energy storage, and they need to be put through their paces in testing to guarantee they can work safely and reliably. Envisys, based in Bangalore, India, is one of the topmost manufacturers and suppliers of battery test chamber products that offer temperature and climatic chambers with a variety of safety packages that are aligned with risk standards, environmental criteria, or test types for conducting lithium-ion battery testing. Envisys’ battery testing chamber products are ideal for performing tests on lithium-ion cells and modules.

Lithium-ion batteries can pose a range of risks when handled. System operators must assess the level of risk and use an appropriate safety concept to mitigate it. Portable electronic equipment has traditionally used rechargeable lithium batteries. Reliability and safety are becoming increasingly critical for electric vehicles. The batteries must work well in both hot and cold temperatures while neither leaking or exploding and providing a safety issue.

Standard Models

| AVAILABLE RANGE | 600, 950 AND 1400 LITRES |

|---|---|

| Temperature | -40 / -70 deg C to 180 deg C |

| RH | 10% to 95% (optional) |

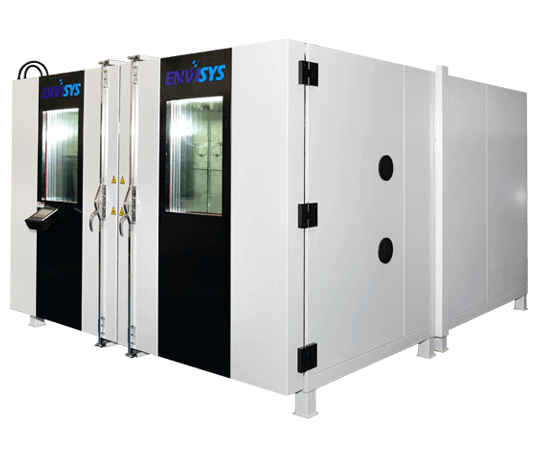

Battery test chamber products are used in different settings, including R&D, quality assurance, and battery manufacture. To suit test needs relating to temperature range, climatic range, and test area size, the packages can be customized to a number of Envisys models. Our custom battery testing chamber products are also exported to developed markets. Regardless of whether testing cells or battery packs, Envisys manufactures high-performance, high-reliability lithium-ion battery testing equipment built to exceed global standard specifications.

Our battery testing chamber products come in a variety of sizes and configurations to accommodate a wide range of battery types. Each chamber is completely designed and meticulously built to meet each product’s testing requirements.

Our customization method also ensures clients’ safety and delivers performance that is specifically suited to clients’ requirements. At Envisys, our battery test chamber products are created and built to satisfy a variety of battery testing needs for our clients, while also considering all safety alternatives to avoid damaging explosions or ignitions, as well as human safety, when evaluating these batteries for environmental stress. The battery testing chamber units come with extensive safety equipment as standard so that tests on lithium-ion cells can be performed at the prescribed hazard level. Moreover, our custom lithium-ion battery testing can safely identify the batteries’ ability to tolerate environmental extremes and stress. Envisys battery test chamber products are ideal for performing tests on lithium-ion cells and modules. Lithium-ion batteries can provide a range of risks when handled. System operators must assess the level of risk and use an appropriate safety concept to mitigate it. Envisys battery testing chamber has a temperature range that may be controlled. The units come complete with significant safety features, allowing lithium-ion cell testing to be performed at an anticipated hazard level.

In this fast-paced era of electronic products, electric vehicles, and storage systems, lithium ion battery testing is critical. Lithium-ion batteries are the most widely used in these items. One of the most important considerations before launching such a product is battery safety. Furthermore, the need for lithium ion battery testing is continuously increasing. Envisys is a leading battery testing chamber manufacturer and supplier has been dedicated to battery safety test research and development. We provide an all-in-one test solution for lithium-ion consumer batteries as well as lithium-ion EV battery packs and modules that meets worldwide test requirements. Our lithium battery test chamber offers a wide range of battery safety test equipment, from environment simulation test chambers to mechanical test chambers, including temperature test chamber, battery crush tester, altitude simulation test chamber, thermal abuse tester, short circuit battery test chamber, t drop tester, shock tester, vibration test system, etc. Smartphones, tablets, wearable gadgets, laptops, house robots, and other electronic products are all around us these days. In such products, rechargeable batteries, primarily Lithium-ion batteries, are extensively used. Both battery and product makers are increasing their demand for battery safety testing. Before sending the battery to clients, they should ensure that it is qualified. Environmental chambers require safety mechanisms to prevent against damaging explosions and assure operator safety because battery failure is a genuine risk (and occasionally a desirable consequence).

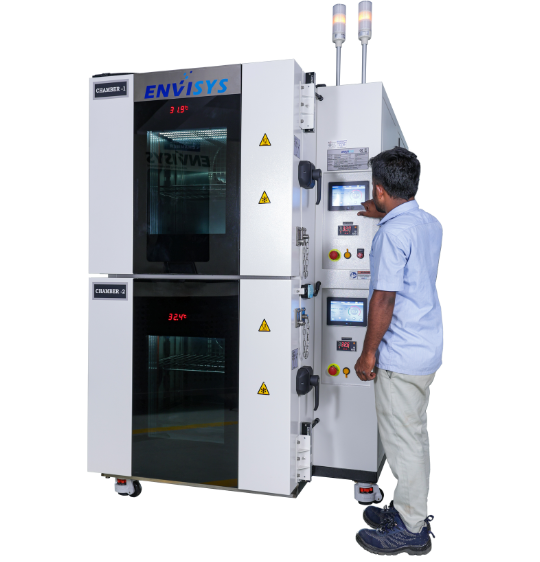

DUAL-STACK BATTERY TEST CHAMBER

The dual-stack configuration maximizes testing efficiency by accommodating multiple battery modules in a compact footprint, allowing for comprehensive, parallel testing of various cell types while significantly reducing space requirements

The release of gases from a battery, which could spontaneously ignite or be ignited by the test chamber’s heaters, poses the biggest danger. Special low-temperature heaters are advised, however extra care may be required. Prior to an explosion, the chamber might be turned off and an alarm sounded by monitoring the battery for thermal runaway. Portable electronic equipment have traditionally used rechargeable lithium batteries. Reliability and safety are becoming increasingly critical for electric vehicles. The batteries must work effectively in both hot and cold temperatures while also not leaking or exploding. Temperature testing with Envisys battery test chamber can safely identify the batteries’ ability to tolerate environmental extremes and stress. Envisys, as a leading lithium battery test chamber manufacturer and supplier, is committed to battery safety research and development, holding numerous technical patents. We continue to create new equipment and improve the battery test system after years of research and manufacturing in collaboration with thousands of customers.

Additional Safety Features

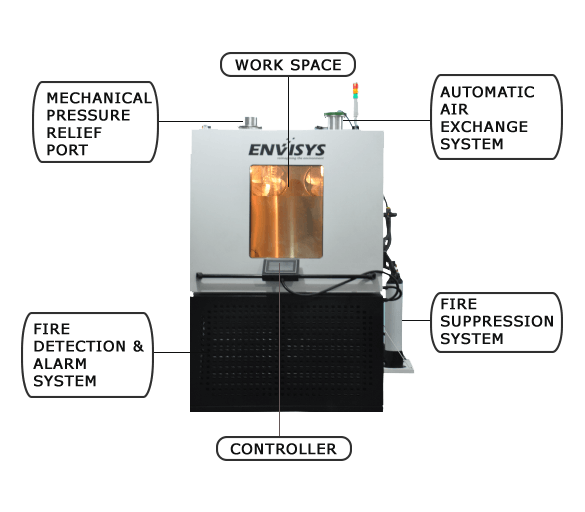

The ETB-Series Environmental Test Chambers for battery testing are designed with all the applicable safety features required for reliability tests and abuse testing of batteries. The Environmental Test Chambers of Envisys for battery testing also covers all the eight EUCAR safety levels as prescribed by the standards and user specific requirements depending on the nature of batteries tested.

Custom Battery Testing Chambers Manufacturers & Suppliers USA, UK, Russia

These Chambers are designed and manufactured to meet various types of battery testing requirements of its customers by keeping all safety options in mind against any harmful explosions or ignitions and user safety while testing these batteries for environmental stress conditions.

- Fire Suppression System (CO2).

- Automatic Air Exchange System.

- Mechanical Locking & Fire Extinguisher System.

- Mechanical Pressure Relief Port.

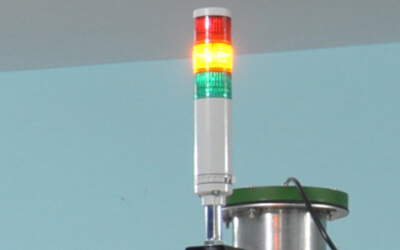

- Fire Detection/Alarm System ( O2 & CO ).

- Status Indication & Smoke Detection.

Battery Testing Chambers

Battery Testing Model

Battery Testing Model

Battery Testing Model