Salt spray corrosion chamber manufacturers suppliers usa uk russia

Salt Spray Fog Test Corrosion Chambers

A salt spray chamber is a lab simulation of a corrosive saline environment. The salt spray test chamber is designed to test the performance of items on their surfaces after corrosive protection treatments such as painting, coating, galvanizing, anodizing, and lubrication. Envisys’ salt spray corrosion chamber is one of the world’s most sophisticated and versatile salt spray test systems, with unrivaled design, ergonomics, and quality.

Salt spray test chamber products also referred to as as salt fog test chambers, are used to assess the resistance to corrosion of metal parts, surface coatings, zinc-plated nuts and bolts, and paint. Coated samples are exposed to an artificial corrosion environment in these salt spray corrosion chambers to check if the coating surface is suitable for use as a protective finish on final products. Samples are tested inside a salt fog chamber for a predetermined amount of time; the higher the corrosion resistivity, the longer the test time in the salt fog chamber.

Everything You Need In A Test Chamber…

Being a prominent manufacturer and supplier of salt spray test chamber products in India, our salt spray chamber products are ruggedly constructed with a maintenance-friendly design and suitable for testing as per ASTM, DIN, GM, JIS, MIL, etc., standards. Our salt spray corrosion test chamber products are used to test the capacity of surface coatings to withstand atmospheric corrosion in an accelerated manner. The exterior of these cyclic corrosion test chamber products is made of a highly corrosive resistant non-metallic glass-fiber-reinforced structure. We manufacture and supply salt fog chamber devices of the highest quality. These corrosion chamber devices are built to last with a maintenance-friendly design and are ideal for testing to IS, BS, ASTM, and DIN specifications.

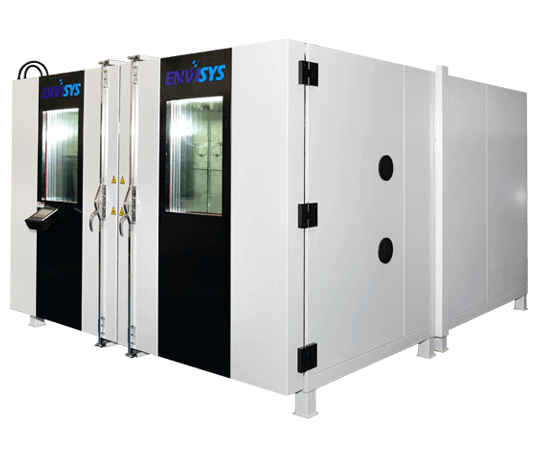

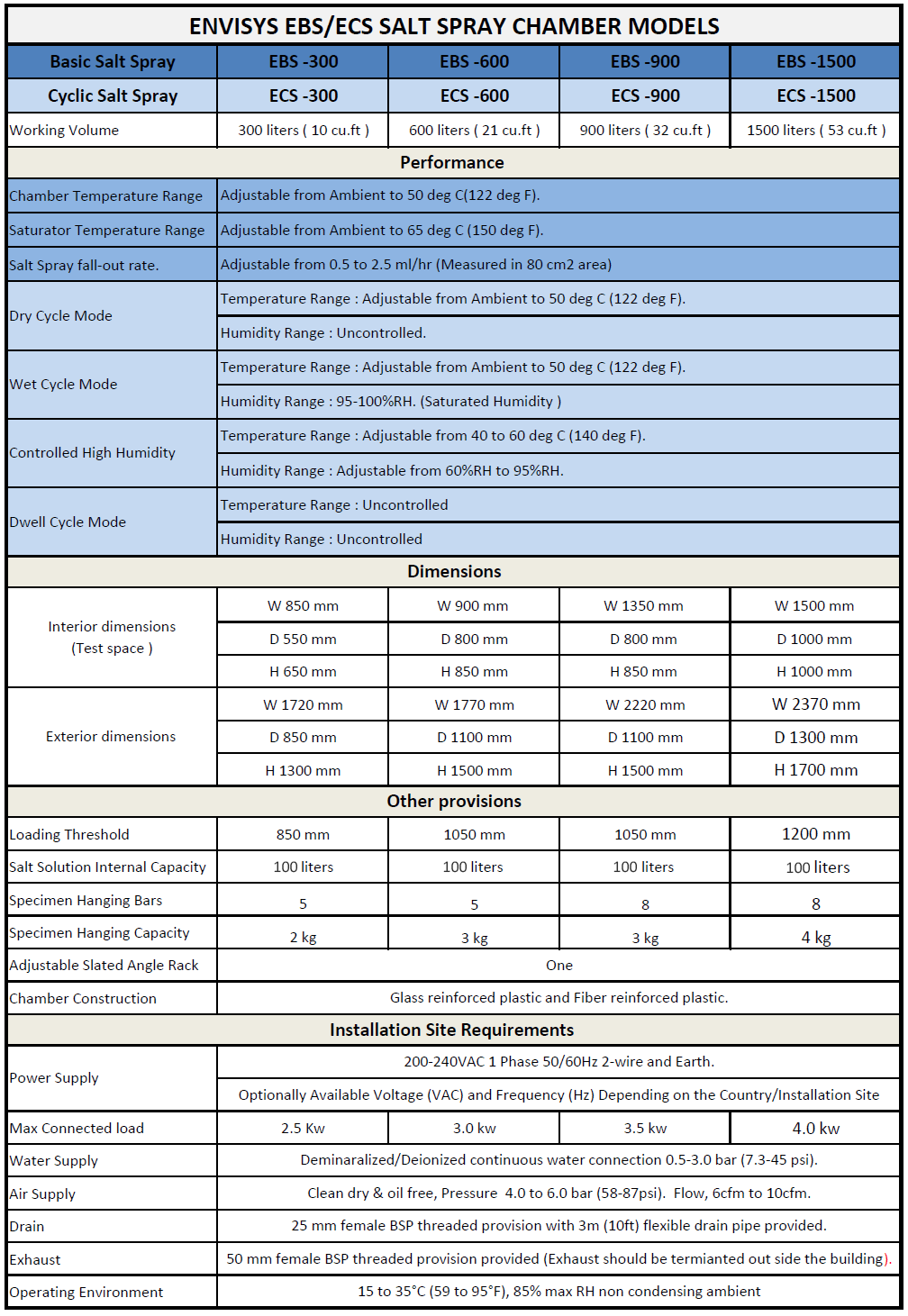

STANDARD MODELS – BASIC & CYCLIC VERSIONS

| Standard Volumes | 300,600,900 & 1500 Liters |

| Chamber Temp | Adjustable from ambient to 50°c |

| Saturator Temp | Adjustable from ambient to 65°c |

| Saturation / Controlled Humidity – optional |

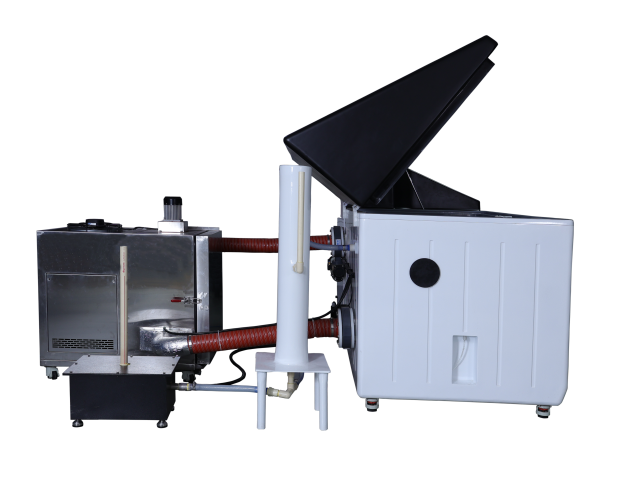

CYCLIC VERSION – FRONT VIEW

CYCLIC VERSION – REAR VIEW

BASIC VERSION – FRONT VIEW

A cyclic corrosion chamber, also known as a salt fog test chamber, is performed in a closed cyclic corrosion test chamber that may be altered to simulate a number of corrosive environments. During testing, samples are exposed to a specific salt concentration for a set duration of time, as established by the specification, product type, or industry norms. At Envisys, our salt spray corrosion chamber experts are highly qualified across several disciplines and our salt fog chamber can be used for a variety of products and applications.

With a global platform of accredited, high-capacity laboratories, we make sure that clients’ projects are accurate, on time, and within budget. Our large-capacity cyclic corrosion chamber can accommodate a wide range of test specimen sizes, shapes, and dimensions. Our salt spray chamber products can also adjust the duration of the exposure for the test to meet the needs of individual clients. We also cater to international markets where the demand for our salt spray test chamber products has been mainly for our innovative engineering and advanced technology. The quality construction, long-lasting durability, and future-proof salt spray chamber performance are unrivaled in the industry.

During operation, Envisys salt spray corrosion chamber maintains two extremely exact temperatures, which is critical for maintaining consistent salt spray concentration and test item cover. The working volume is defined as one-tenth of the measure of each axis toward the center of the test chamber. The volume within the cyclic corrosion chamber exposed to high precision temperature uniformity is defined by these minimal measures, which are size-dependent.

The temperature gradient and the temperature variance in space are the two averages that makeup temperature uniform. The average difference between the operating temperature in the middle of the cyclic corrosion test chamber and numerous different arbitrary places around the salt fog chamber is known as temperature variation in space. The temperature gradient is the average difference in operating temperatures between the discretionary points of the salt mist chamber. Envisys guarantees that your salt spray corrosion chamber devices will be evaluated under consistent, repeatable, and consistent environmental conditions.

The high-reliability thermostatic temperature controller in Envisys salt spray test chamber products keeps the salt solution at a preset temperature in a reservoir within a double-wall construction. Envisys cyclic corrosion chamber products are one of the world’s most modern and adaptable salt spray chamber test equipment, with unrivaled design, ergonomics, and quality. From continuous salt spray tests to condensation humidity and modified tests, cyclic corrosion test chamber products are available to meet every testing need.

We are committed to providing salt spray mist chamber devices that satisfy the needs of our valued customers. Our corrosion test chamber is professionally crafted from high-quality materials in accordance with industry standards. Our quality controllers test these spray chambers to ensure their flawlessness. Customers can obtain these cyclic corrosion test chamber equipments from us within a predetermined time limit.

SALT SPRAY CHAMBER WITH REMOTE REFRIGERATION

SALT SPRAY CHABER WITH VIEW WINDOW

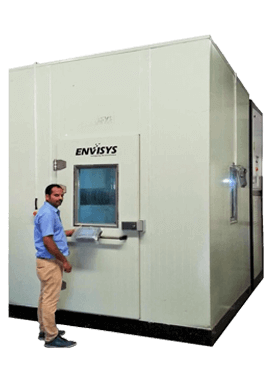

WALK-IN SALT FOG CHAMBERS

Optional control consoles as per customer choice for Basic and Cyclic versions

Single Set Point PID Controller OR Color Touch Programmer

Basic Version

- Integrated control panel.

- Temperature control system will be single set point.

- Microprocessor based PID controller with precise temperature control.

Cyclic Version

- Touch screen based complete user-programmable console capable of controlling chamber & saturator temperature, perform cyclic operations

- Individual event selection of dry cycle, high humidity cycle etc.

- Min 5 Nos of programmable timers for alarm activation.

CONTROL CONSOLES

OPTIONAL ACCESSORIES

| ECS-01 | Optional Accessory for Renault D172028 (ECC-1) |

| ECS-02 | Remote Refrigeration Unit RRU/A1, RRU/A2 |

| ECS-03 | Spray Header Cycle (Vertical Down) |

| ECS-04 | Immersion Test Cycle |

| ECS-05 | Wall Wash |

| ECS-06 | SO2 Gas Dozing |

| ECS-07 | De-Humidifier Unit |

| ECS-08 | Multi-Solution Salt Spray |

| ECS-09 | Drain Treatment Unit |

EMS-SERIES

MINI – Salt Spray Chambers

Space Saving & Cost Competitive

MODEL: EMS-100

VOLUME: 100 Litres Work Space Dimensions: 600 x 500 x 400 MM

More Information

Standard Models

After sale service is an integral part of our business: Our services include complete technical and engineering support to our customers round the clock, repair, maintenance, refurbishments, spare parts etc.,

Varieties of

Salt Spray Chambers

Cyclic Version – Mid Range

Basic Version – Mid Range

Mini-Salt Spray Chamber

Walk-in Salt Fog Chamber

Walk-in Salt Spray Chambers