Thermal Shock Chambers Manufacturers Suppliers USA UK Russia

Thermal Shock Environmental Test Chamber | Thermal Cycling Chamber

Thermal shock environment chamber testing is applied to products to observe their features and failures induced by multiple materials and their thermal expansion coefficients. The thermal shock test chamber involves feeding the chamber at alternating high and low temperatures. Also known as a temperature cycling chamber, the thermal shock chamber is used to test the long-term impact of a wide range of temperatures on a product or part’s quality parameters.Thermal shock testing simulates the significant temperature variations that a product may see in real-world use by users. Consider the shock a smartphone battery gets when someone goes from chilly winter weather outside to the comfort of their own house. For example, imagine leaving an airport runway in 95°F weather and then reaching peak altitude in -40°F to -70°F temps.

Thermal shock chamber products examine the durability of objects and find breaking points by contrasting extremes of hot and cold air. This method is less likely to be used by failures. The thermal shock test chamber has two zones: one for heat and another for cold, with a third zone for ambient temperature as a backup.

Envisys’ industrial thermal shock chamber products are used by many of the world’s major firms to test goods for electronics, automotive, defence, aerospace, and various other industrial applications. We have a wide range of thermal cycling chamber products that allow alternating between heating and cooling materials including composites, plastics, and ceramics. We are one of the top thermal shock environment chamber manufacturers and price and cost-effective suppliers of thermal shock test chamber products.

Our thermal shock environment chamber aids in determining the performance of the tested material in extreme settings involving temperature changes in relation to humidity variations. The tests might be static in nature or dynamic in nature to induce and cause failure. By identifying our client’s needs, developing exceptional test equipment, and going above and beyond with our comprehensive services, we strive to surpass their expectations. As the number one thermal shock environment chamber manufacturers and price

We take pride in providing innovative and complete turnkey solutions to clients as one of the leading manufacturers and suppliers of thermal shock environment chamber products globally.

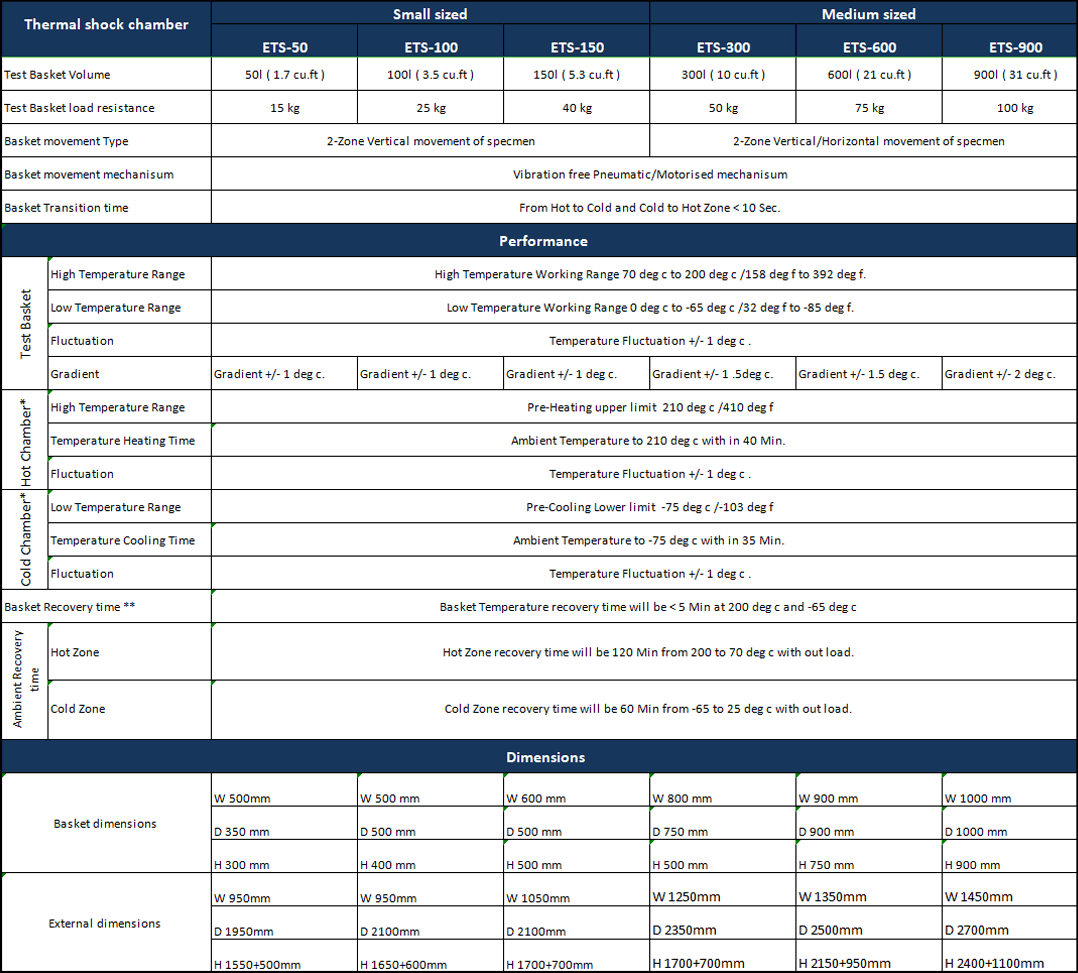

| Standard Volumes | 150,300,600,950&1400 Liters |

| Temperature | -40 / -70°C to 200°C +/- 1°C |

| Basket Transition Time | < 10 Secs |

For businesses, product reliability is paramount. Envisys produces industry-leading temperature cycling chamber products to help companies ensure their goods can tolerate fast temperature fluctuations. Our thermal shock test chamber products have been used to test electronic components in the automotive, aerospace, and military industries, and have resulted in advancements as well as peace of mind for businesses and consumers. The thermal shock chamber has been designed to help clients get the most out of their thermal testing.

Our thermal shock chamber products come in a variety of sizes to enable various sorts of product testing. Thermal shock environment chamber products are used to test component and board electronic assemblies for environmental stress. Our innovative temperature cycling chamber design transports the product between two temperature-controlled chambers, passing equal quantities of conditioned air over the product and resulting in quick temperature changes. By expanding and contracting key elements, induced heat stresses can uncover latent manufacturing faults in electronic sub-assemblies and other components.

Envisys recognises this need in the business and elevates it by building it around its vision of satisfying clients. This unbridled enthusiasm drives its team to collaborate with clients at every level of thermal shock test chamber development, resulting in a product that gives a complete testing experience. Furthermore, we believe in delivering high-quality thermal cycling chamber products on time and providing excellent after-sales service. We are a prominent thermal shock chamber manufacturer and one of the most cost-effective suppliers of thermal shock chambers as compared to others, without sacrificing quality.

Envisys’ thermal shock environment chamber is a useful instrument for conducting thermal shock tests on items. A product carrier basket in a thermal shock test chamber transfers a product under test between temperature zones that are independently controlled. Users may easily monitor the product as it is transported between different temperature zones thanks to built-in viewing windows.

Thermal shock chamber products from Envisys are available in different volumes to suit the varied testing needs. Horizontal or vertical models consisting of cold and hot zones with product carrier baskets of sizes 50, 100, 150, 300, 600, and 900 liters which transfer the specimen under test between cold and hot zones using electro-pneumatic / motorized basket movement.

The temperature cycling chamber at Envisys undergoes a number of technological changes to reduce total test duration and temperature recovery time while maintaining excellent homogeneity. The result achieved demonstrates constant accuracy in temperature recovery and homogeneity across several test cycles, enhancing the chamber’s test reproducibility and dependability.

Most test items are subjected to air-to-air thermal shock testing, in which the test item is mechanically moved from one extreme atmospheric temperature to another. Envisys uses a series of vertical two-zone thermal shock chambers in which an elevator transfers tiny to medium-sized pieces from one extreme to the other almost instantly. Thermal shock test chamber products are totally enclosed to prevent unintentional exposure to ambient temperature and handling dangers.

Envisys also supplies fixtures and the proper configuration to meet applicable test specification criteria while ensuring the safety of the test object for very large items that cannot be moved by an in-chamber elevator. The hot and cold zones are separated inside the chamber by specially engineered gaskets to prevent leaking between them. The temperature cycling chamber can achieve faster recovery rates thanks to a specially constructed test basket with reduced thermal mass and a powerful temperature-conditioning device. The thermal shock test chamber can be tailored to meet the needs of the test. As one of the foremost thermal shock environment chamber manufacturers and price and cost affordable suppliers, Envsiys offers a unique chamber that sets the industrial standard for thermal cycling.

STANDARD MODELS

Thermal Shock Chambers

ETS50-Thermal Shock Chamber

ETS100-Thermal Shock Model

ETS150-Thermal Shock Model

ETS300-Thermal Shock Model