Environmental test chambers utms

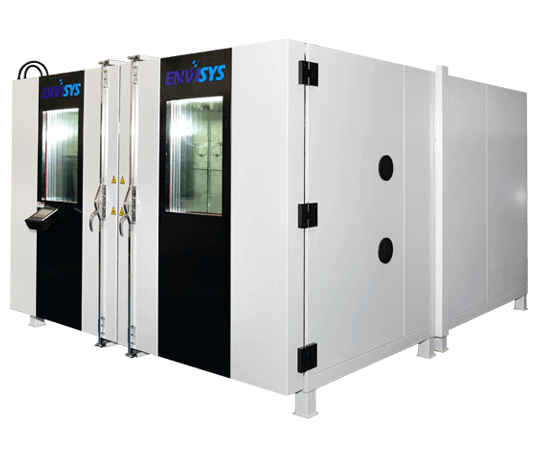

UTM Interface Environmental Test Chamber

ETU-Series UTM Interface Environmental Test Chamber for conducting environmental tests at elevated and freezing temperatures in order to perform integrated tests for hot & cold conditions on universal testing machines.

Temperature-Relative Humidity-Salt Fog Integrated Test Apparatus for UTM Interface is designed to meet the specific test requirement of integration test, for this application, test enclosure is designed for the rig interface in split units, for this from the RC (Remote conditioning) unit purge the conditioning air to test enclosure.

STANDALONE FEATURES OF CHAMBERS:

- Designed in custom sizes as per the requirements.

- Temperature range +/-30 / +/-65 to 80 deg and 20% to 95% RH.

- Control features are optional.

Top and Bottom of the chamber with UTM Interfacing slots and covering.

Top and Bottom of the chamber with UTM Interfacing slots and covering.

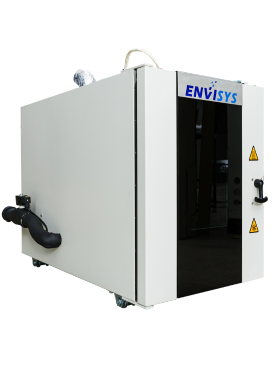

UTM Miniature Chambers

UTM Miniature Chambers

Environmental Test Chamber integrated with Universal Testing Machines.

Environmental Test Chamber integrated with Universal Testing Machines.

With over 40 years of expertise in the field, Envisys has a thorough understanding of environmental testing. It is because of this heritage that we have been able to lead the way in the design, manufacture, and supply of a wide range of UTM interface environmental test chambers. Irrespective of the level of testing complexity needed, we assist our clients with our robust testing solutions, unrivalled level of flexibility, and exceptional client support.

In a modern, cutting-edge laboratory, tensile and compression testing devices, often known as UTMs (Universal Testing Machines), are critical in generating reliable data. Envisys, a premier manufacturer and supplier of UTM interface environmental test chambers in India as well as overseas in countries like the USA, UK, and Russia, offers a wide range of chamber solutions to our customers. All solutions are custom-built to match the user’s exact needs, ensuring consistent and accurate data collecting and testing.

An environmental chamber can be purchased with a universal testing machine (UTM), or an UTM interface environmental chamber can be added to the testing system later if temperature testing becomes necessary after the UTM is acquired. Integrating Envisys environmental chamber to a universal testing machine (UTM) allows for high- or low-temperature testing. Environmental chambers come with their own temperature controller, and the temperature settings and observations are controlled by the UTM’s controller or software, depending on the system’s compatibility. Moreover, our UTM interface environmental test chamber makes and models have different specifications, and the two classes of testing machines, d servo-hydraulic testing frames and electromechanical, come with different mechanical designs.

Our high and low-temperature UTM environmental system allows materials and equipment to be tested in a range of real-world scenarios. The UTM interface environmental test chamber can perform a wide range of tests at low and high temperatures. In a modern, cutting-edge laboratory, tensile and compression testing devices, are critical in generating reliable data. Our UTM environmental test chamber is ideal for tension, compression, bending, peel and tear tests in a variety of fields, including metal wire, plastic, nylon wire, rubber, textile and apparel, packaging, and so on. Envisys currently offers a wide range of chamber solutions to our customers. For particular industries, such as steel manufacturing, glass manufacturing, ceramics, and aerospace, Envisys material testing aims to simulate the real-world application in order for the results to be valid. As a result, testing may demand high-temperature or low-temperature settings. All solutions are custom-built to match the user’s exact needs, ensuring consistent and accurate data collection and testing.

UTM Interface Environmental Chamber