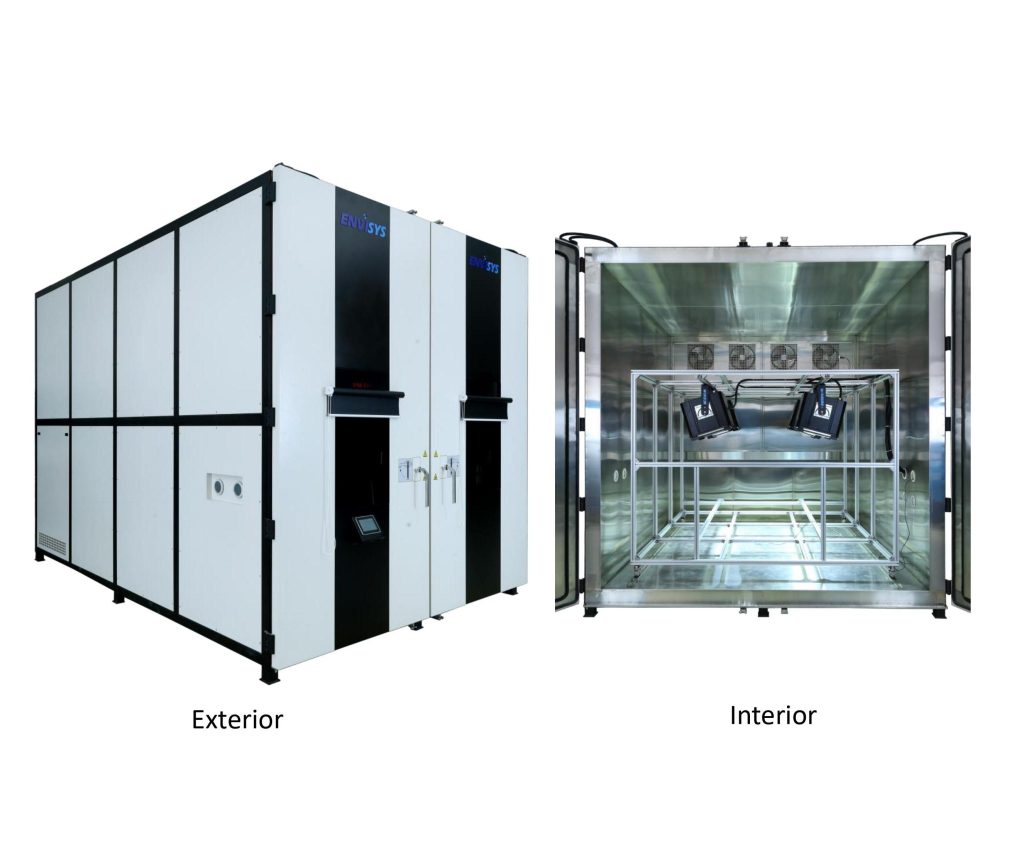

Solar simulation chambers are meticulously designed to accurately replicate temperature, climatic conditions (temperature with humidity), and global solar irradiation, both indoor and outdoor conditions. These chambers enable the replication of sunlight effects on various products and facilitate comprehensive testing of crucial parameters such as performance, insulation, noise, and resistance to physical and mechanical losses. By subjecting products to simulated sunlight exposures, it helps manufacturers evaluate the impact on material integrity, color fading, and overall product lifespan.

The solar simulation chambers are available in different versions, including standard, energy-saving, and highspeed

cooling, providing flexibility to meet diverse testing requirements. With sophisticated construction and high-quality workmanship, Envisys ensures exceptional temperature and humidity consistency, resulting in precise and reliable test results.

With Envisys’ specially designed solar simulation chambers, manufacturers can confidently evaluate the impact of sunlight exposure on their products. By leveraging Envisys’ technical expertise, deep industry knowledge, and commitment to excellence, customers can benefit from tailored solutions that meet their specific needs.