Envisys provides high-quality Climatic test chambers in UK, Russia, USA & India. The climatic test chambers or the environment test chambers test the behavior of the products in challenging climatic conditions. It tests the stability, endurance, and practicality of products and equipment.

Here is a short guide for you to know about climatic test chambers, their varieties, and their application area. Further, we will help you understand the trend for opting for the best climatic testing services for testing your products. So, let us know the various aspects of choosing the best climatic chamber for industrial requisite!

What is a climatic test chamber?

A climatic chamber, or a climate chamber, is a managed, enclosed, and controlled environment that tests the effects of various climatic conditions on industrial products, stability and endurance of biological products, and other chemical and electronic components.

Indeed, these chambers can create extreme environmental variations, especially in terms of temperature, including moist or humid and functional radical altitude changes to test the applicability of the product.

What are climatic test chambers- floor level?

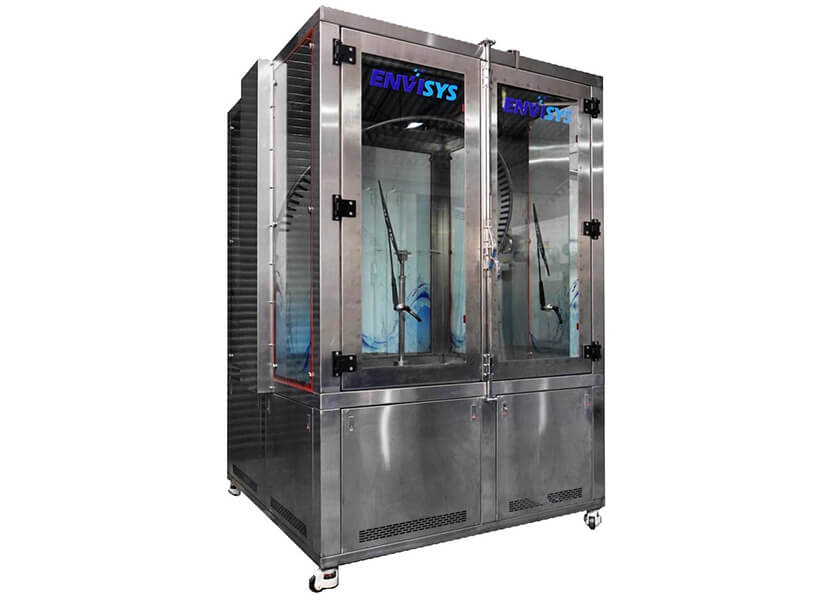

Envisys manufactures and designs environmental test chambers for floor-level loading of equipment under test.

It offers relative humidity tests of -70 to 180 degrees C and provides 10% to 98% relative humidity conditions.

Different Types of the climatic test chamber

The design of climatic test chambers or the environment test chambers allows it to perform more than one type of test. Yes, these chambers help you save money and time while checking the viability of any new product. Following are some of the types of climatic chambers.

Mechanical test chambers

These chambers perform mechanical tests. And thus, they are applicable to determine the variations in shock, hardness, impact, and vibrations.

Walk-in test chambers

Indeed, the chambers are large enough for any person to walk in! The size may vary from the huge ones to fit a truck or a vehicle to requirements of small closets. The walk-in chambers are functional to carry a full range of tests, including salt-spray, temperature testing, and thermal shock tests.

Steady test chambers

The steady chambers perform long-term shelf life material testing. Indeed, the steady test chambers can effectively stimulate an extensive range of humid temperatures and environments.

List of products that can undergo tests with the climatic test chamber

Testing a range of products in various fields is essential, from an electronic perspective to automotive requirements.

- Telecom products, including industrial drivers

- Automotive products, including the batteries

- Industrial grade components for mass production

- Production materials

- Solar panel testing

- PV modules testing

- Electronic devices including mobile phone testing.

Explore the types of test chambers- floor level

The climatic test chambers at Envisys have uncompromised designs to meet the varying needs of simulations. Explore an extensive range of test chambers to match industrial testing needs.

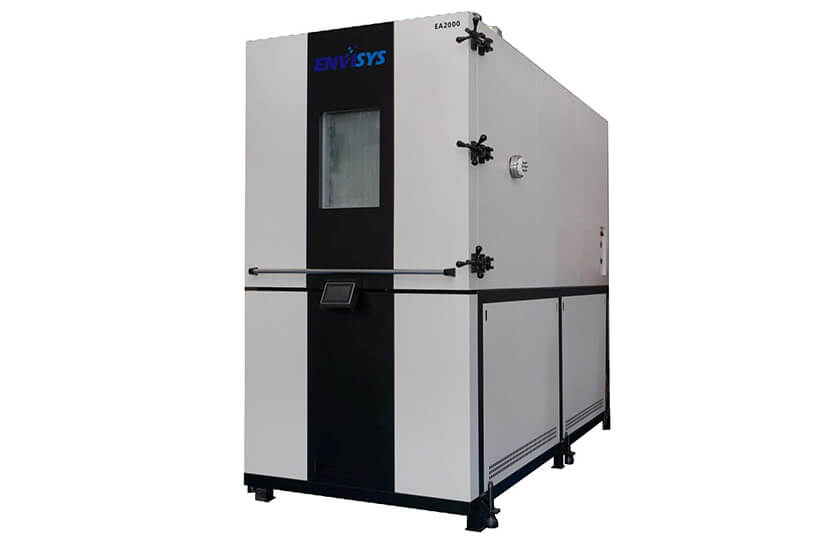

Environmental test chamber for floor level loading

It includes floor level loading of a device under test (DUT) for relative humidity tests and temperature tests.

Dry Heat Chambers

These testing chambers test the temperature for drying, aging, curing, burning and various temperature testing applications.

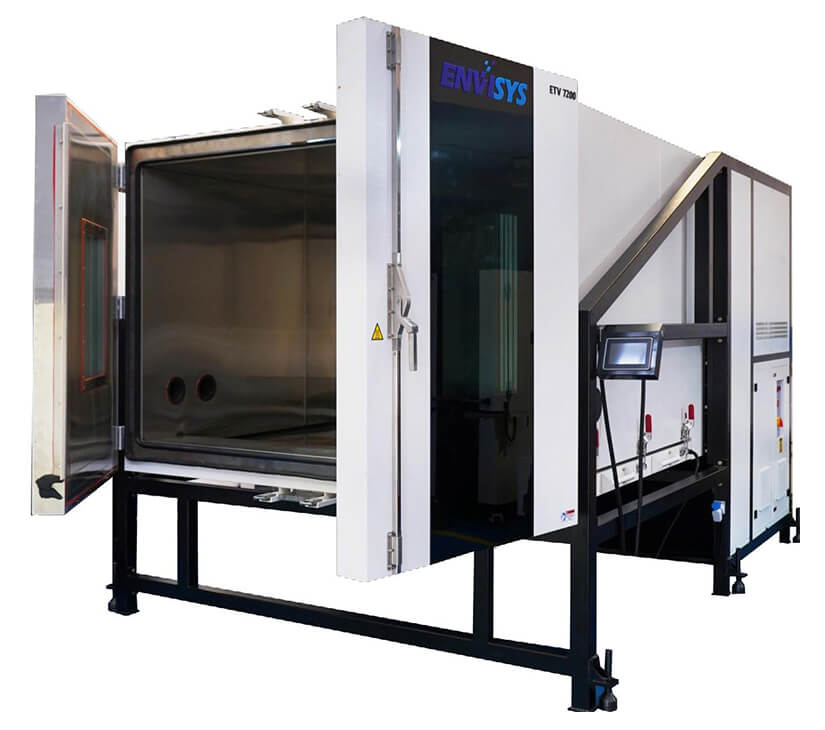

Walk-in Climatic Test Chambers or Drive-in Climatic Test Chambers

These testing chambers are larger in size to perform climatic tests or environmental tests on a larger sized specimen viz., vehicle level testing wherein the specimen load will be heavy and needs to be loaded from floor into the test chamber using ramping.

Environmental Stress Screening Chambers or ESS Chambers

It fulfills the environmental stress screening testing requirements wherein the climatic test chamber or environmental test chamber with floor model is capable for simulating the temperature profiles with high ramp rates to meet the stringent testing requirements of ESS tests as per international standards like MIL, IEC, DIN etc.,

Envisys designs various other testing chambers, including PV modules and solar panels testing, batteries testing, altitude chambers, and many more! Explore the best testing chamber to match your requirements.

Applicability of climatic test chambers for various Industries

Test chambers help professionals study the efficacy of products for automotive, artificial intelligence, aerospace, medicine, solar cell, and various other industrial research requisites.

Additionally, while these chambers provide a reliable, economical, and convenient method for studying various products, it helps in effective product development. Here is a brief on the industries that use climate test chambers.

Automotive Industry

These test chambers help recreate possible vehicle conditions. The test results allow the engineers to efficiently accelerate the factors to determine the resilience of the materials.

Defence and Aerospace industry

Testing of atmospheric or environmental conditions to practically adhere to stringent SAE standards is necessary for Aerospace scope. Test chambers help test for reliability, quality, and safety. Moreover, it includes testing of electronic equipment, including satellites and antennas.

Electronics and Tele-communication industry

Indeed, testing of all kinds of electronic components and end products calls for qualification to environmental or climatic testing requirements as per various international standards. Testing procedure of each electronic component or end product varies from one to another.

Services and solutions provided by Envisys

Envisys provides a spectrum of effective climatic testing services. It includes repair services, refurbishments, maintenance contracts, rental services with available calibration, and sound technical consultations.

Refurbishments

We refurbish old climatic test chambers or systems to refurbish them according to the latest technology and make it new for reuse.

Repair services

Envisys provides all kinds of services for test chambers. We also repair and inspect for any further issues for break-down chambers.

Rental services

We have rental facilities for a selected category of environment chambers, available on a monthly, daily basis. The rental services are currently limited to India.

Testing services

Envisys also has a testing lab which offers the testing services on hourly basis. Right now Envisys test lab has got Environmental Test Chambers, Salt Spray Test Chambers, Dust Chambers, Drop Testing, Rain Chambers, Industrial Oven etc.,

How are our climate chambers adequate for your business?

Using our Climatic Chamber or Environmental Chamber will suffice the testing requirements of various types of products for wide range environmental simulations in the confined work spaces as required by the size and weight of the specimen for testing. We can bring extreme environmental simulations to your doorsteps by supplying our custom-designed environmental climatic test chamber as per your requirements.

These testing chambers are best as they include effective testing against the listed conditions:

- Extreme temperature and sudden variations

- Altitude

- Salt spray

- Electromagnetic radiation

- RH or moisture

- Cyclic corrosion testing, and many more!

Conclusion

Envisys provides a range of climatic test chambers in UK, Russia, USA & India. Being the leading manufacturer of test chambers, we understand the importance of genuine testing for manufacturing industries.

Get the best environmental test chamber- floor level to simplify your industrial needs from Envisys!