Have you ever wondered how electronic companies ensure temperature control for their device under various circumstances? How does a car manufacturer design its warranty? Or how your phone’s battery does not catch fire when left under the sun?

The companies undertake environment testing, especially those producing electronic goods, automobiles, and devices operating on rechargeable electronic batteries. The products undergo rigorous testing under different conditions.

The Environmental test chamber USA identifies the areas of weakness in designs for customer satisfaction.

What are Environment Test Chambers?

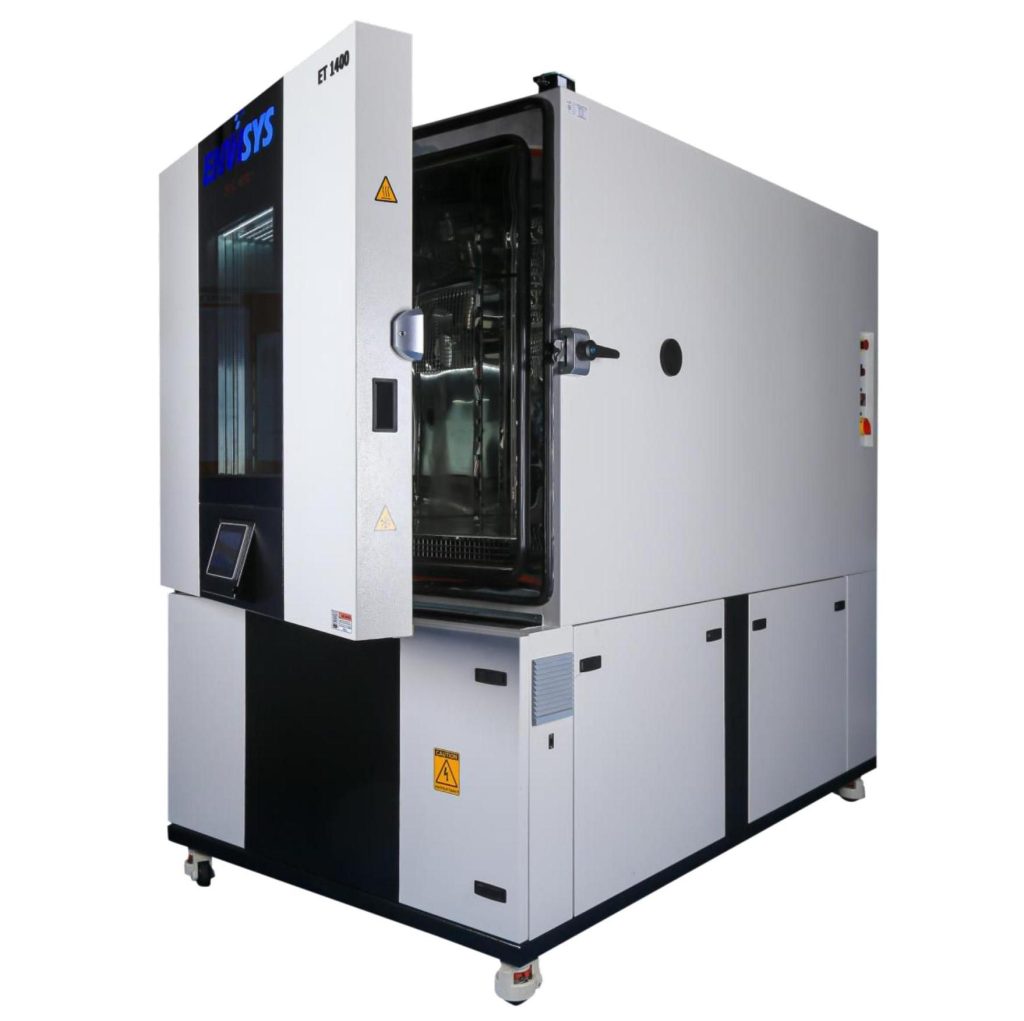

The engineers use an environment chamber from the walk-in environmental test chamber supplier Iowa to subject different sensor assemblies to extreme temperatures. It mimics, manages, and controls factors like humidity, air pressure, light, motion to test the product stability. In this system, the users manipulate various environmental conditions within an enclosed space and run controlled tests on the subjects. The engineers and researchers utilize this to ensure if the product is safe and operational. Custom Environmental test chamber California is available in varied sizes ranging from half cubic feet (benchtop) to 12,000 cubic feet (drive-in rooms). These test chambers have a longevity of 10 years. Purpose of the test chamber – Additional testing of the product Stand-alone testing for differently combined materials Stress screening to identify product issues while at the prototyping stage

Types of Environmental Chambers

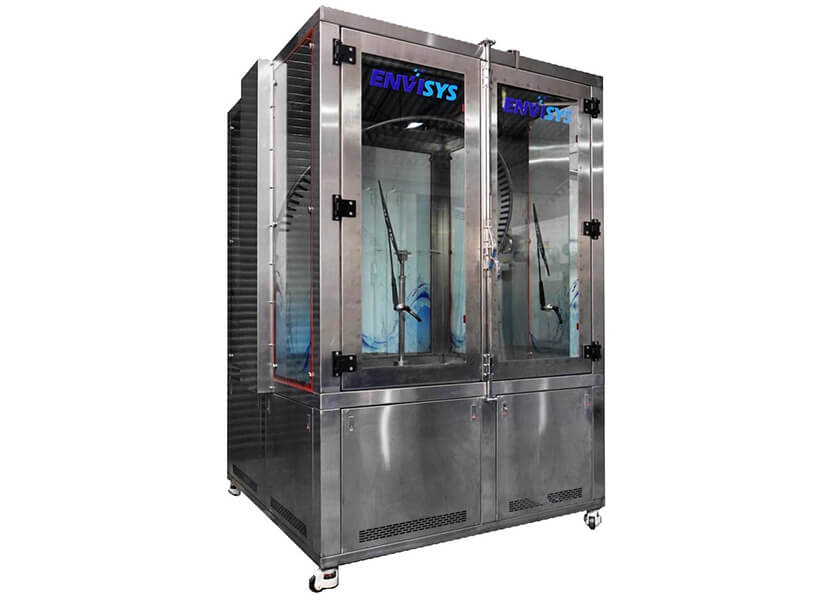

- Walk-In Test Chambers

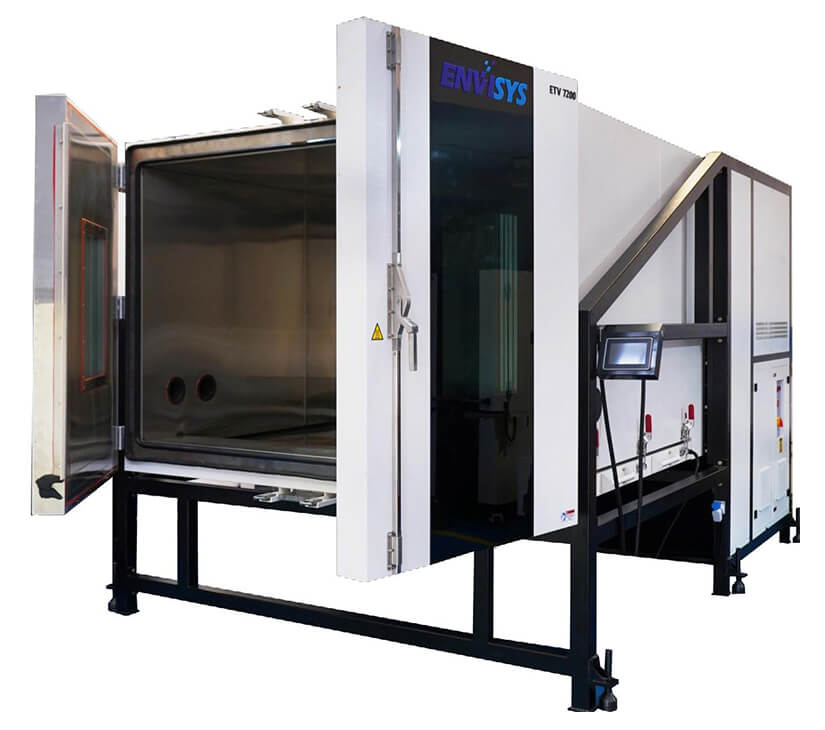

- Modular Chambers

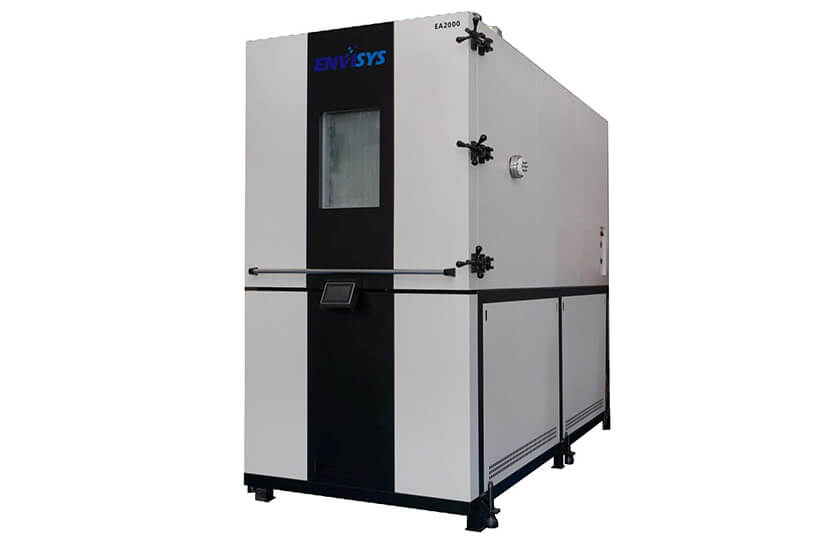

- Steady Test Chambers

- Table Top Test Chambers

- Vacuum Test Chamber

- Welded Test Chamber

- Stability Chambers

- EMC or Anechoric Rooms

- Cryogenic chambers

- Pressure Chambers

How do Environmental Chambers Function?

The test chambers use heating and refrigeration systems to create a range of conditions and control temperature. The steam generators add or remove moisture, the saltwater environment in the salt spray solutions force the inside of the chamber from the compressed air tank. The precise temperature controls give accuracy in final readings. Most chambers have temperatures ranging between -80° C or -112° F to +300° C or +672° F. The thermal cycling chambers operate through pre-set temperatures, eliminating the need for an operator. You can purchase a good quality product from the walk-in environmental test chamber supplier Iowa.

Advantage of Using Environmental Chambers in the USA

For manufacturing companies in the US, environment test chamber calibration can generate premium results. •Product Life Cycle testing •Climactic Detection •Environmental Stress Screening •Consistent measurements •Precision in the product quality •Establishes product reliability •Traceability and adherence

Importance of Using Environmental Chambers

Companies conduct environmental chamber testing for products at different stages of their life cycle. This is to identify the weak points. Eventually, they can measure the production downtime and assess the problem areas for rectification. Effective research is essential to notice advances in engineering technology. Companies do research and development to plan, design, and deliver new products. They also measure its distinct performance metrics. You can buy from the environmental test chamber manufacturers Texas to check the product’s shelf life by stimulating external conditions. A change of five degrees inside the test chamber is equal to two years in the real world. Once you understand the project’s longevity, you feel confident to launch it in the market. For Production testing, the producers test every device with HASS or Highly Accelerated Stress Screening. Individual testing fulfills certain company requirements to achieve a balance in time, effort, and resources. But whatever be the method, this time legitimizes all the labor that goes into R&D.

You have to assess the products regarding their quality and reliability before they are sold to the markets for the public. The testing can also authorize the time & money involved in the R&D. The Environmental test chamber USA also assists with quality testing and reliability testing. Quality assurance determines the level of product excellence. Its survival capacity in different situations implies the device’s dependability. It becomes an instant success while at par with regulatory standards and the manufacturer’s specifications. Reliability Testing is also done under environmental conditions. It checks performance under high and low temperatures. It also reduces the risk of costly repair and unexpected failures.

Benefits of Envisys Environmental Chambers

Envisys is a reputable designer and manufacturer of environmental test chambers of the highest quality. We integrate our products with ingenious designs and strategies for high-level functioning. Our environmental test chambers can meet all your requirements via the simulation of temperature, relative humidity, and much more. We make them feature-rich without compromising on quality. We are one-in-all environmental test chamber manufacturers Texas, making a variety of standard models. The product characteristics go beyond normal customer expectations. There is no added cost, and you can fit in specimens of varying sizes.

Why Envisys as Manufacturer and Supplier of these Chambers?

The environment chambers manufacturing done by the engineers at Envisys is feature enriched. We are a designer of Custom Environmental test chamber California selling our products at affordable prices. •LED illuminated work-space, de-fog heaters •Multi-pane glass view & vacuum protected •CRCS powder coated panels and high-grade SS interiors •Durable shelving, adjustable tray channels •Double layered silicone rubber sealing, di-casted, heavy-duty aluminum locks •Auto tuning •Three-level security Rely on our products for remote monitoring of the test chamber. We guarantee high standard performance using a state-of-the-art facility. This way, we promise satisfying results to our customers across the USA.

Conclusion

For large industrial and manufacturing companies in the USA, especially those situated around Texas, Iowa, and Massachusetts, the walk-in environmental test chamber supplier in Iowa offers plenty of benefits. It helps enhance the product development life cycle while ensuring its longevity and safety. The excellence it renders is a guaranteed proven solution for various applications. Envisys majorly contributes to the growth of the US market for extensive custom-made projects, a one-stop approach to successful environmental testing.